Laundry Pod/Capsule Making Machine for High-Concentration Detergent XZ300

Machine profile:

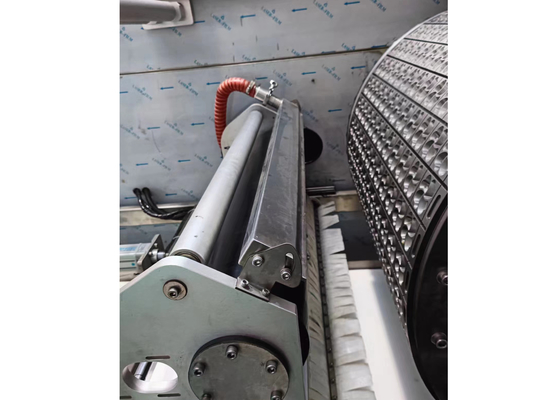

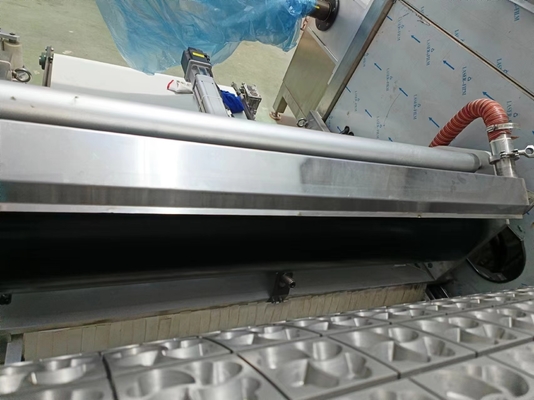

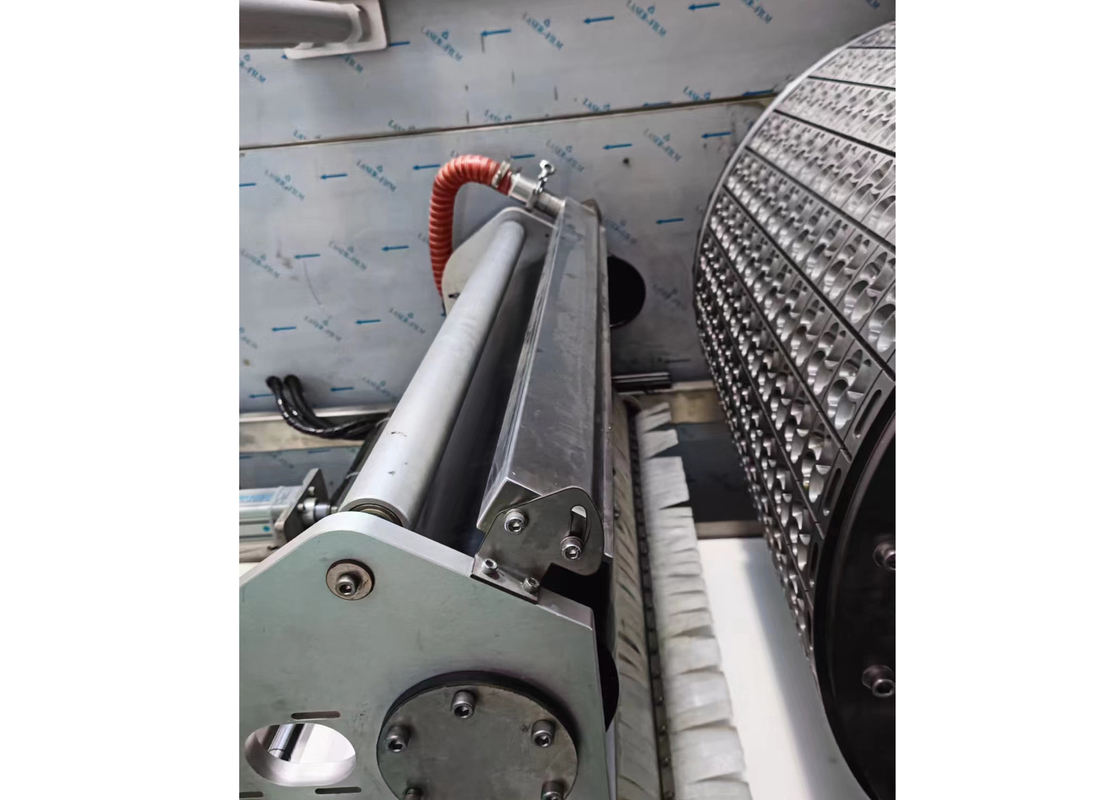

Laundry coagulation machine XZ300 is a drum type single cavity or multi-cavity small dose liquid special automatic forming and filling equipment, is specially developed for laundry detergent, non-water system oil, chemical individual quantitative packaging and a high-speed automatic packaging machine, with good film and liquid agent adaptability. The XZ series molds are replaceable and the mold system is easier to clean and maintain. Easier maintenance and maintenance for seasonal boot use. It is especially suitable for small dose quantitative packaging of pesticide cream preparation, high concentration laundry detergent, chemical oil preparation and other non-water systems. It is the preferred packaging method for enterprise product upgrading.

Parameter description:

Synchronous ratio (water cover/spindle) : the function is to adjust the water cover of the film, the ratio is the ratio of the water cover servo motor and the spindle servo motor, the purpose is to adjust the relative speed of the PU drum, so as to adjust the amount of film cover water, the adjustment of this parameter for the bottom film and the above compound plays a crucial role.

Synchronization ratio (chain/spindle) : The function is to adjust the speed of the longitudinal cutter, this ratio is the ratio of the chain supporting the washing ball servo motor and the spindle servo motor, the purpose is to adjust the traveling speed of the film and the linear speed of the chain, to ensure the accurate cutting of the longitudinal cutter.

Spindle single theoretical pulse number: the function is to adjust the roller mold to travel a cavity spindle servo need to send the number of pulses.

Single theoretical pulse number of chain: The function is to adjust when the drum mold walks a mold cavity, the chain walks an arc length corresponding to the number of pulses that the chain servo motor needs to send.

Specifications:

| Model |

XZ300 |

| filling heads |

12 |

| Color |

Gray |

| Bottle Width |

Single cavity or multiple cavity |

| Noise |

30-45 decibels |

| Ambient humidity |

38% |

| Suitabe range |

Single cavity or multiple cavity |

| Production Capacity |

≤500 pcs/min |

| Filling Error |

±0.2% |

| Material |

SUS304 |

| Warranty |

12 month |

| Contour dimensions |

2825*2000*2200

|

Competitive Advantage:

1. This filling machine is mainly made of SUS304 or SUS316L.

2. The machine conforms to GMP standard, easy to disassemble, clean and maintain.

3. PLC programmable control is adopted.

4. 6-inch touch screen man-machine interface system.

What services can Changzhou Xianfei Packing Equipment Technology Co., Ltd. provide for you?

1. Product inspection

We have our own factory and quality control department, and we will check carefully to ensure the quality of the products before sending them to our customers

2. Sample services

We can send you a video of the machine in action.Welcome to visit our company and have a look at the machines being produced in our factory

3. Customization services

A: We can customize the machine according to the mechanical power, materials and bottles you provide

B: We can also offer you some professional advice on machinery.As you know, we have been in the machinery business for 16 years.

4. About install

We can provide installation.There are two options.

The first option: We can send our engineers to your company for debugging and maintenance, and your company will bear the cost of air ticket, visa, accommodation, labor and other expenses for this trip.

Option 2: Offer an online service.

Tag: weight filling maching,automatic filling machine

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!